Blog

Top 10 Load Break Isolators You Need to Know for Safe Electrical Systems

In the realm of electrical systems, ensuring safety and reliability is paramount. One of the crucial components that plays a vital role in achieving this is the Load Break Isolator. These devices serve as essential protective measures, allowing for the safe isolation of electrical circuits from the power source during maintenance or emergencies. Understanding different types of Load Break Isolators and their applications can significantly enhance the safety protocols of any electrical installation.

As we delve into the top 10 Load Break Isolators you need to know, we will explore their functionalities, advantages, and best practices for integration within various electrical systems. Each isolator is designed to handle specific operational demands, making it important for engineers and technicians to familiarize themselves with their characteristics. Implementing the right Load Break Isolator not only contributes to optimal performance but also minimizes risks associated with electrical hazards.

With the rapid advancement of technology and the increasing complexity of electrical networks, selecting the appropriate Load Break Isolator has never been more critical. This guide aims to provide insights into the best options available, equipping professionals with the knowledge necessary to make informed decisions for safeguarding electrical systems.

Overview of Load Break Isolators in Electrical Systems

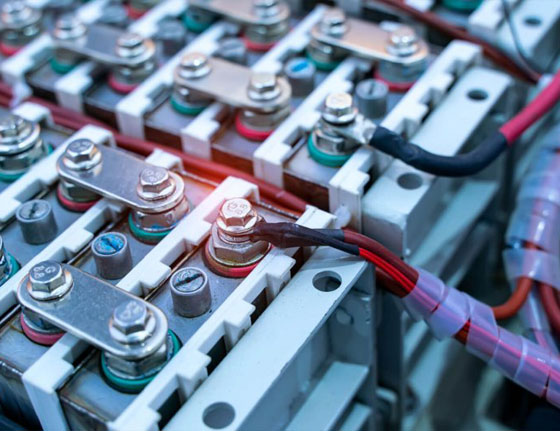

Load break isolators are essential components in electrical systems, serving the critical function of disconnecting circuits under load conditions. These devices are designed to safely isolate a section of the electrical network for maintenance and repair, minimizing the risk of electrical arcs and ensuring the safety of personnel. By providing a clear demarcation point within the system, load break isolators facilitate systematic procedures in managing electrical distribution and maintaining overall system reliability.

The operational principle of load break isolators ensures that they can interrupt the current flow before disconnection occurs. This ability to break the circuit while it is still energized is critical for both safety and operational efficiency. In practice, these isolators enhance the safety protocols in place, as they allow technicians to work on specific segments of the system without completely shutting down the entire network. By integrating load break isolators into electrical systems, organizations can effectively manage their infrastructure, ensuring resilience and continuity in power supply while safeguarding human operators during maintenance activities.

Key Features and Benefits of Load Break Isolators

Load break isolators are critical components in ensuring the safety and reliability of electrical systems. These devices are designed to interrupt the flow of electricity under load conditions, providing a safe means for maintenance and reducing the risk of electrical faults. One of the key features of load break isolators is their ability to maintain system integrity by isolating power during repairs or upgrades, thus minimizing downtime. According to a report by the International Electrotechnical Commission (IEC), the adoption of such isolators can reduce maintenance-related accidents by up to 30%, significantly enhancing workplace safety.

Another notable benefit of load break isolators is their ability to provide a visual indicator of the isolation status, which is crucial for operators in ensuring that the system is properly de-energized before maintenance. The fault rating and voltage level capabilities of these isolators also contribute to their performance, making them suitable for various applications, including industrial and commercial installations. A study published in the Journal of Electrical Engineering reveals that systems utilizing load break isolators can limit the consequences of electrical failures by more than 50%, further underscoring their importance in safe electrical system design.

Top 10 Load Break Isolators: Key Features and Benefits

The chart above displays the key features rating of the top 10 load break isolators available in the market, assessed on a scale of 1 to 10. The ratings highlight their effectiveness and reliability in ensuring safe electrical systems.

Top 10 Recommended Load Break Isolator Brands and Models

When selecting load break isolators, understanding the top brands and models is crucial for ensuring the safety and reliability of electrical systems. The market is replete with options, but several key players have set themselves apart based on industry standards and performance metrics. According to the International Electrotechnical Commission (IEC), the right load break isolator can significantly reduce short-circuit risks and improve overall grid stability, making it imperative to choose wisely.

Among the top recommendations are isolators designed with advanced technology that enables quick disconnection during maintenance or in emergencies. Features such as robust insulation, compact design, and enhanced durability are essential considerations. Reports indicate that isolators with a weather-resistant rating have a longer lifespan and lower failure rates in outdoor applications, which is particularly relevant for utilities operating in diverse environmental conditions.

Tips: When choosing a load break isolator, always check for compliance with IEC and ANSI standards to ensure you are getting a quality product. It's also beneficial to consult with professionals who can provide insights based on operational requirements and installation environments. Investing time in understanding the specifications and performance history of each model can help you make informed decisions that protect both personnel and infrastructure.

Top 10 Load Break Isolators You Need to Know for Safe Electrical Systems

| Model | Rated Voltage (kV) | Current Rating (A) | Installation Type | Features |

|---|---|---|---|---|

| Model A | 12 | 630 | Outdoor | Mechanical Interlock |

| Model B | 15 | 800 | Indoor | Remote Operation |

| Model C | 24 | 1000 | Combined Indoor/Outdoor | IP68 Rated |

| Model D | 36 | 1200 | Pole-Mounted | Arc Quenching |

| Model E | 12 | 630 | Modular | Integrated Protection |

| Model F | 15 | 500 | Switchgear | Easy Maintenance |

| Model G | 24 | 800 | Floor-Mounted | Fault Detection |

| Model H | 36 | 1000 | Panel-Mounted | Smart Technology |

| Model I | 12 | 400 | Compact | Energy Efficient |

| Model J | 15 | 800 | Pod-Mounted | Advanced Safety Features |

Understanding Applications and Use Cases for Load Break Isolators

Load break isolators are vital components in electrical systems, providing a means to safely isolate equipment during maintenance or in emergency situations. Their primary application lies in high-voltage environments, where they protect both personnel and equipment from electrical faults. By facilitating the breaking of load current, these isolators help prevent arc formation, ensuring a safer working condition for technicians. This ability to disconnect live circuits is crucial in substations, industrial facilities, and commercial buildings where electrical safety is paramount.

In addition to their protective functions, load break isolators also serve various operational purposes. They are widely used in renewable energy systems, such as wind and solar power installations, to safely disconnect the generation equipment from the grid during fault conditions or system upgrades. Another notable application is in switchgear systems, where they ensure reliable isolation of transformer or circuit sections without interrupting the entire electrical network. These use cases exemplify the adaptability and necessity of load break isolators in promoting the reliability and safety of modern electrical infrastructures.

Safety Standards and Regulations for Load Break Isolators

When it comes to ensuring the safety and reliability of electrical systems, adherence to safety standards and regulations for load break isolators is paramount. Load break isolators play a critical role in isolating electrical circuits during maintenance or fault conditions, allowing technicians to work safely without the risk of electric shock or equipment damage. These isolators are designed to perform under specific criteria set forth by international and national electrical standards, which encompass aspects such as construction, performance, and testing protocols.

Various organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), provide guidelines that govern the operation and implementation of load break isolators. Compliance with these regulations ensures that isolators can withstand certain thermal and mechanical stresses, thereby maintaining safety during operation. Furthermore, regular audits and inspections are essential in verifying that these devices meet the specified standards, ultimately contributing to the overall safety of the electrical system and its users.