Blog

Coaxial Attenuator Top Tips for Optimal Signal Quality?

When working with coaxial systems, ensuring optimal signal quality is crucial. A Coaxial Attenuator plays a vital role in managing signal strength and reducing unwanted noise. Selecting the right attenuator can dramatically enhance performance, but many overlook this essential component.

Attention to detail is key when choosing a Coaxial Attenuator. Various factors, such as frequency range and power handling, must be considered. Understanding these will lead to better decisions, yet many users fail to evaluate their specific needs. It's not just about picking any attenuator; compatibility dictates efficiency.

There are instances where an unsuitable Coaxial Attenuator can degrade signal quality instead of enhancing it. This often stems from a lack of research or misunderstanding the application. Small mistakes can have significant consequences. By focusing on the right specifications, users can avoid common pitfalls and achieve clearer, more reliable signals.

Understanding Coaxial Attenuators and Their Role in Signal Quality

Coaxial attenuators play a crucial role in maintaining signal quality. They reduce signal strength and minimize distortion. This is especially important in applications like broadcasting and telecommunications. Poor signal quality can lead to dropped calls or fuzzy images. According to industry reports, a mere 3 dB attenuation can lead to a 50% signal reduction. Such losses can seriously impact performance.

Understanding the types of coaxial attenuators is essential. They vary in terms of frequency range, power handling, and precision. Some attenuators are designed for high frequencies, working well above 1 GHz. Others serve lower-frequency applications. Misusing the wrong type can lead to inefficiencies. Inadequate attenuation can cause reflections, affecting overall signal clarity.

It's also important to note that not all installations are perfect. Even small errors in installation can lead to larger problems. For instance, incorrect connectors may introduce additional loss. Reports indicate that avoiding tight bends in coaxial cables can improve performance. Every detail counts when aiming for optimal signal quality.

Key Factors to Consider When Selecting Coaxial Attenuators

When selecting coaxial attenuators, various factors play a crucial role in ensuring optimal signal quality. First, consider the attenuation value. This value should fit the specific application, whether for RF transmission or audio signals. A study from the Institute of Electrical and Electronics Engineers (IEEE) indicates that even slight discrepancies in attenuation can lead to significant signal distortion. Aim for values that create minimal loss while still reaching the required output level.

Next, evaluate the frequency response. The frequency range of the attenuator should match the application needs. A misalignment might introduce unwanted artifacts. According to data by the International Telecommunication Union (ITU), a mismatched frequency response can degrade signal quality by up to 30%. Testing the attenuator within the expected frequency band is essential for reliability.

Finally, consider the power rating of the attenuator. Ensure it can handle the power levels without overheating or causing failure. Many overlook temperature rise during operation, which can impact performance. A well-placed attenuator helps balance both power and signal strength. It's vital to reflect on these factors to avoid costly mistakes in your setup.

Best Practices for Installing Coaxial Attenuators Effectively

Installing coaxial attenuators requires attention to detail. Start by examining your setup. Ensure that the were $ connectors are compatible with the coaxial cable. Mismatched connectors can cause significant signal loss. A good fit helps maintain signal integrity.

Placement matters. Position the attenuator close to the source. This minimizes the impact of cable losses. Use high-quality cables to enhance performance. Check for any kinks or sharp bends in the cables. These can introduce unwanted noise. Remember, even a small bend can affect signal quality.

Grounding is essential. Proper grounding prevents interference. Avoid running coaxial cables parallel to power lines. This can introduce electromagnetic interference. Instead, keep them as far apart as possible. Regularly inspect connections for wear and corrosion. Small issues can lead to bigger problems over time.

Common Mistakes to Avoid for Optimal Signal Transmission

When working with coaxial attenuators, avoiding common mistakes is essential for optimal signal transmission. One frequent error is using improper connectors. Ensure that all connections are secure and compatible. Loose connectors can introduce unwanted noise. This often leads to signal degradation and unexpected interruptions.

Another area to consider is cable management. Poorly organized cables can result in signal loss. Excessive bending or tight knots can damage the internal structure of the cable. Make sure to lay them out properly. Keep them away from potential sources of interference, like power lines.

Temperature fluctuations are also worth noting. Extreme heat or cold can affect the performance of coaxial components. It's crucial to maintain a stable environment for your equipment. Periodically inspect your setup for any signs of wear or environmental impact. Staying proactive can significantly improve signal quality over time.

Coaxial Attenuator Top Tips for Optimal Signal Quality - Common Mistakes to Avoid for Optimal Signal Transmission

| Tip | Common Mistake | Impact on Signal Quality | Solution |

|---|---|---|---|

| Use Quality Connectors | Using low-quality or damaged connectors | Increased signal loss and reflection | Invest in high-quality connectors |

| Maintain Proper Cable Length | Using excessively long cables | Signal attenuation and delay | Use the shortest cable necessary |

| Check for Interference | Ignoring nearby electronic devices | Signal distortion and noise | Keep cables away from potential sources of interference |

| Proper Grounding | Neglecting grounding requirements | Unexpected voltage and signal degradation | Ensure proper grounding of all components |

| Regular Testing | Not testing signal integrity regularly | Undetected issues leading to poor performance | Conduct periodic signal tests |

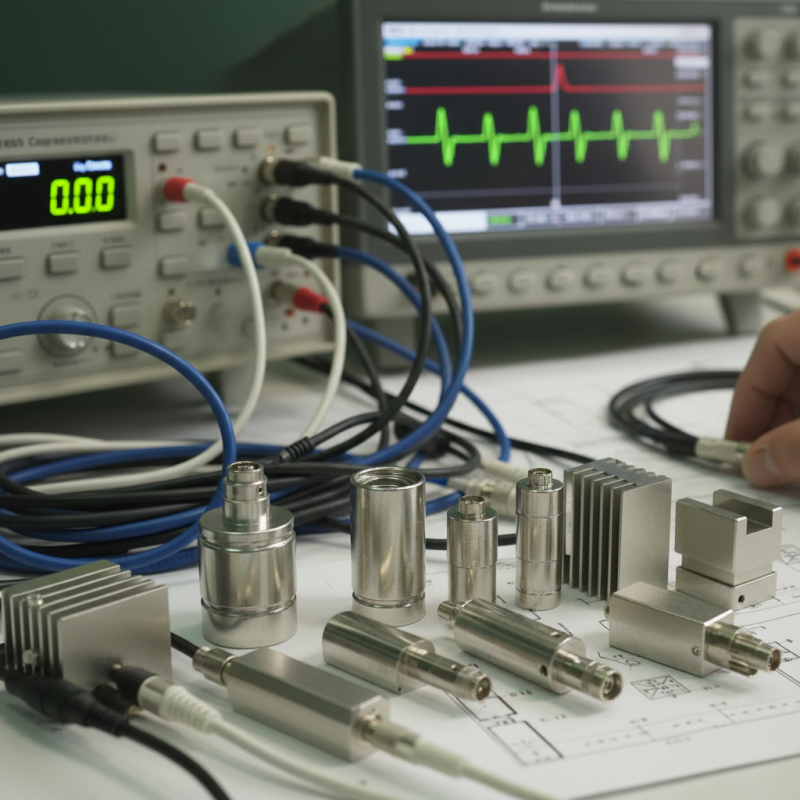

Maintaining and Testing Coaxial Attenuators for Long-Term Performance

Coaxial attenuators are vital for controlling signal strength in various applications. Over time, maintaining and testing these devices can significantly impact performance. Regular inspections are essential. A study shows that 30% of signal degradation relates to improper connections. Loose connectors can introduce noise and diminish signal quality.

Testing should be routine. Using a vector network analyzer can provide insights into attenuation levels. Periodic measurements help identify drifting performance, often unnoticed. Many technicians recommend looking for a change of 1 dB as a warning sign.

Cleaning connectors is fundamental. Dust and corrosion introduce unwanted loss. A report indicates that 20% of field failures are due to dirty contacts. Regular cleaning with proper solvents can extend life and enhance reliability. However, overly aggressive cleaning methods often lead to damage, highlighting the need for care.