Blog

How to Choose the Right Load Isolating Switch for Your Electrical Needs

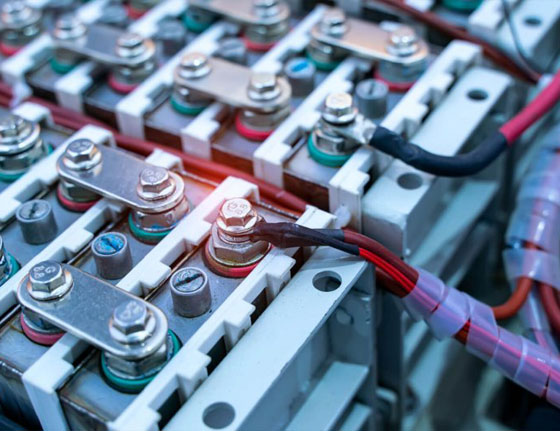

When it comes to ensuring the safety and efficiency of electrical systems, selecting the right Load Isolating Switch is crucial. A Load Isolating Switch serves as a vital component in electrical installations, allowing for the safe disconnection and isolation of electrical circuits from their power sources. This not only protects the personnel working on the system but also ensures that the equipment remains undamaged during maintenance and troubleshooting processes.

In order to make an informed decision, one must consider several factors—including the switch's current and voltage ratings, environmental conditions, and the specific requirements of the electrical system. Understanding the differences in construction and operational capabilities among various Load Isolating Switches can also greatly impact their performance and longevity. As electrical installations often face unique challenges, choosing the right switch tailored to your specific needs can enhance safety, reliability, and efficiency while minimizing downtime and operational risks.

In this guide, we will explore key considerations to keep in mind when selecting the appropriate Load Isolating Switch to meet your electrical requirements effectively. By diving into the essential features and operational characteristics of these switches, we aim to empower you to make knowledgeable choices that align with the demands of your electrical setup.

Understanding Load Isolating Switches and Their Functionality

Load isolating switches play a crucial role in electrical systems, allowing users to safely disconnect power from specific circuits. These devices are integral for maintenance, protecting both equipment and personnel from unforeseen electrical hazards. According to the International Electrotechnical Commission (IEC), proper use and selection of load isolating switches can enhance system reliability and reduce downtime, leading to improved operational efficiency. Furthermore, a report from the National Electrical Manufacturers Association (NEMA) indicates that well-implemented isolation solutions can mitigate up to 25% of unexpected electrical failures.

Understanding the functionality of load isolating switches is essential for making informed decisions. These switches are designed to handle load currents and provide a visual indication of the power status, proving essential in maintenance scenarios. With the average lifespan of electrical equipment in commercial settings pegged at around 15-20 years, using the right switch can significantly impact long-term operational costs. The decision process should consider factors such as current rating, environmental conditions, and installation type, as highlighted in recent studies by the Electrical Safety Foundation International (ESFI), which emphasize the importance of adherence to current safety standards in the selection process.

Choosing the right load isolating switch is not just about functionality; it's about understanding the operational environment and ensuring compliance with industry regulations. As the demand for safe and reliable electrical systems grows, so does the necessity for informed choices in switch selection, with projections indicating a market growth in load isolating technology by 10% annually over the next five years. This underscores the importance of investing in high-quality isolating switches tailored to specific electrical needs.

Key Factors to Consider When Selecting a Load Isolating Switch

When selecting a load isolating switch, several key factors should be considered to ensure it meets your electrical needs effectively. One crucial aspect is the switch’s rated voltage and current. According to a report by the International Electrotechnical Commission (IEC), the voltage rating should generally exceed the maximum system voltage to avoid breakdown. For instance, if your system operates at 400V, opting for a switch rated for at least 450V is advisable, thereby providing a margin of safety. Similarly, the current rating must align with the expected load; an undersized switch can lead to overheating and increased maintenance costs.

Another important consideration is the location and environmental conditions where the switch will be installed. According to industry standards set forth by the National Electrical Manufacturers Association (NEMA), switches used in outdoor environments must have appropriate ingress protection (IP) ratings to withstand dust and moisture. For example, an IP65 rating signifies that the switch is protected against water jets and dust ingress, which is crucial for outdoor applications. Additionally, if the switch will be exposed to extreme temperatures, selecting a switch designed to operate in those conditions will enhance its reliability and lifespan. By carefully evaluating these factors, you can select a load isolating switch that ensures safe and reliable electrical operations tailored to your specific requirements.

Types of Load Isolating Switches and Their Applications

Load isolating switches are essential components in electrical systems, providing a means to safely disconnect load circuits from power sources. Various types of load isolating switches are designed to cater to different applications and requirements. One common type is the rotary isolator, which operates through a simple rotating mechanism. These switches are ideal for low-voltage applications in residential and commercial buildings, allowing for easy visual indication of the switch position when isolating circuits.

Another prevalent type is the knife switch, which features a metal blade that can be moved to open or close the circuit. Knife switches are typically used in high-voltage applications, providing a robust method to isolate equipment for maintenance and safety. They are often found in industrial settings and substations, where reliability and durability are crucial. Lastly, the fused isolator combines the load isolating switch with fuses for additional safety. This type is particularly effective in protecting circuits from overloads and short circuits, making it suitable for environments with variable loads or sensitive equipment. Each type of load isolating switch serves a unique function, and understanding their applications is vital for making the right choice for your electrical needs.

Installation and Maintenance Guidelines for Load Isolating Switches

When installing a load isolating switch, proper attention to detail is essential to ensure safety and functionality. Begin by selecting an appropriate location that can accommodate the switch and provides easy access for manual operation. The area should be dry and free from any hazardous materials to minimize potential risks. Ensuring proper clearance and ventilation around the switch is also crucial for maintaining optimal performance and preventing overheating.

Tips: Always check local electrical codes and regulations to confirm compliance and safety standards. It’s advisable to consult with a certified electrician if you’re unsure about the installation process or electrical requirements.

Routine maintenance is integral to the longevity and reliable operation of load isolating switches. Regularly inspect the switch for any signs of wear, corrosion, or damage. Keep the switch clean by removing dust and debris that may accumulate over time, as this can affect its functionality. Ensure that all connections are secure, and consider testing the switch monthly to verify that it operates smoothly.

Tips: Document maintenance activities and inspections to track the switch's condition over time. This practice can help identify any recurring issues and facilitate timely repairs, enhancing the switch's performance and safety.

How to Choose the Right Load Isolating Switch for Your Electrical Needs

| Feature | Description | Importance |

|---|---|---|

| Current Rating | The maximum continuous current the switch can handle. | Critical for preventing overheating and failure. |

| Voltage Rating | The maximum voltage the switch is designed to operate under. | Essential to ensure proper operation within electrical systems. |

| Installation Location | Location where the switch will be installed (indoor or outdoor). | Influences the type of switch needed (weatherproof vs. standard). |

| Switch Type | Manual, electrical, or smart switches. | Determines ease of use and functionality. |

| Compliance Standards | Standards the switch adheres to (e.g., IEC, UL). | Ensures safety and reliability in usage. |

| Maintenance Requirements | Frequency and type of maintenance needed. | Long-term operational efficiency and safety. |

Safety Standards and Compliance for Load Isolating Switches

When selecting a load isolating switch, it's imperative to ensure that the product complies with relevant safety standards. Standards such as IEC 60947-3 and UL 98 outline essential requirements for performance, safety, and reliability. Compliance with these standards not only ensures the switch can effectively handle load isolation but also minimizes risk in electrical systems. Always check for certification labels and documentation that confirm adherence to these standards before making your purchase.

Tips: Familiarize yourself with local electrical codes, as they may dictate specific requirements for load isolating switches within your region. Always consult with a qualified electrician if you're unsure about which safety standards apply to your project.

Additionally, consider the environment in which the switch will be installed. Extreme temperatures, humidity, and exposure to dust or chemicals can impact the performance of load isolating switches. Ensuring that the switch is rated for its specific environment will enhance both safety and longevity. Regular maintenance checks can help identify any wear or potential issues before they become dangerous.

Tips: Schedule routine inspections of your load isolating switches, ensuring they remain compliant with established safety standards over time. This proactive approach can help prevent electrical failures and promote a safer working environment.